The digital cylindrical printing process involves inserting a cylinder-shaped item, or part, into a fixture, which securely holds it in place. The more advanced systems available on the market can handle these requirements.

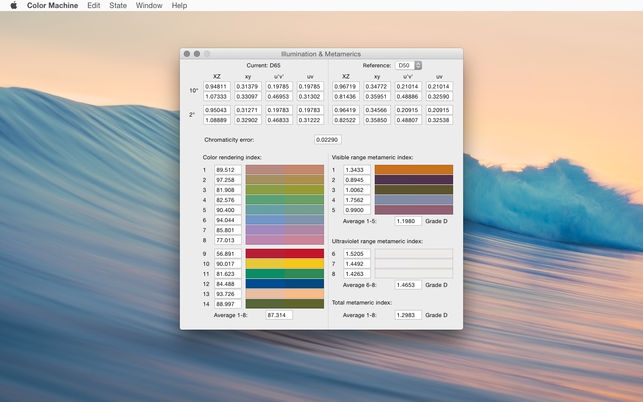

#PRINT COLOR MACHINE SOFTWARE#

For ease of print file preparation, original design artwork should be able to be imaged on cylinders and tapered items without the need for manipulation or distortion i.e., flat images will print to scale on a curved surface, with software automatically making the adjustment. Stained glass: color opaque enough to see throughįull-wrap cylindrical printing also benefits from seamless borders with no visual overlap.Tone on tone: solid matte-finished substrate enhanced with one ink or clear coat.Mirror prints: viewable on the inside and outside of glass or plastic.

#PRINT COLOR MACHINE FULL#

The ability of digital cylinder printing machines to print full color in one pass, including primers, varnishes and specialty inks, enables multiple design techniques, which include: This in turn enables reduced run lengths. The digital process is by definition faster than conventional screen printing, because it requires fewer production steps and less set-up time for multiple colors and more complex jobs. Digital cylinder printing is a method of reproducing black-and-white or full-color images and text onto cylindrical objects, typically promotional products, through use of digital imaging systems. In large format prints, the greatest advantage is that, since no lens is used, there is no vignetting or detail distortion in the corners of the image.ĭigital printing technology has grown significantly over the past few years with substantial developments in quality and sheet sizes.ĭigital cylinder printing is when a machine directly lays ink onto a curved surface that usually is the wall of an object that has a circular cross section, and a constant, tapered, or variable diameter. The archival quality of the print is as high as the manufacturer's rating for any given photo paper used.

These prints are true photographs and have continuous tone in the image detail.

Thousands of print shops and digital printmakers now offer services to painters, photographers, and digital artists around the world.ĭigital images are exposed onto true, light sensitive photographic paper with lasers and processed in photographic developers and fixers. Many terms for the process have been used over the years, including "digigraph" and "giclée". Experimental artists often add texture or other media to the surface of a final print, or use it as part of a mixed-media work. Inkjet printing has the added advantage of allowing artists to take total control of the production of their images, including the final color correction and the substrates being used, with some artists owning and operating their own printers.ĭigital inkjet printing also allows for the output of digital art of all types as finished pieces or as an element in a further art piece. Inkjet reproductions can be printed and sold individually in accordance with demand. Substrates in fine art inkjet printmaking include traditional fine-art papers such as Rives BFK, Arches watercolor paper, treated and untreated canvas, experimental substrates (such as metal and plastic), and fabric.įor artists making reproductions of their original work, inkjet printing is more expensive on a per-print basis than the traditional four-color offset lithography, but with inkjet printing the artist does not have to pay for the expensive printing-plate setup or the marketing and storage needed for large four-color offset print runs. The IRIS printer was the standard for fine art digital printmaking for many years, and is still in use today, but has been superseded by large-format printers from other manufacturers such as Epson and HP that use fade-resistant, archival inks ( pigment-based, as well as newer solvent-based inks), and archival substrates specifically designed for fine-art printing. Initially, these printers were limited to glossy papers, but the IRIS Graphics printer allowed the use of a variety of papers that included traditional and non-traditional media. There was experimentation with many of these types of printers, the most notable being the IRIS printer, initially adapted to fine-art printing by programmer David Coons, and adopted for fine-art work by Graham Nash at his Nash Editions printing company in 1991. It evolved from digital proofing technology from Kodak, 3M, and other major manufacturers, with artists and other printers trying to adapt these dedicated prepress proofing machines to fine-art printing.

Large format printing of black numbers on a brushed aluminum sheet by a Mimaki inkjet printerįine art digital inkjet printing is printing from a computer image file directly to an inkjet printer as a final output.

0 kommentar(er)

0 kommentar(er)